Electroless Nickel – The Coating of Choice for Many Applications!

Last month Sheffield published our first blog post, providing a brief introduction to our owners, the history of the company and a review of our current core competencies; electroless nickel, gold, silver, SPI Connector Black, PTFE and Cadmium plating. These chemistries cater specifically to the Hermetic, Connector and Aerospace industries to name a few.

This blog post is going to dive head-first into one of the core competencies mentioned above, Electroless Nickel (EN).

Ready?

- Electroless Nickel plating is a chemical reduction process which depends upon the catalytic nickel ions in an aqueous solution, (containing a chemical reducing agent) and the subsequent deposition of nickel metal without the use of electrical energy.

- Electroless Nickel plating houses offer EN plating with varying amounts of phosphorus content in the reducing agent.

- These variations are often referred to as Low Phosphorus, Medium Phosphorus, and High Phosphorus Alloys. Low Phosphorus EN usually has between 1-4% phosphorus in the chemical deposit, while Medium Phosphorus EN has between 5-9% phosphorus.

- Anything greater than 9% phosphorus is referred to as High Phosphorus EN.

- The variation of this phosphorus content in the EN plating deposit has significant impact on the mechanical properties of the deposit and the applications that deposit can be applied to.

Wow, that was a mouthful. In layman’s terms, Electroless nickel uses a displacement reaction, meaning a thin zinc layer is applied to the base material; in this case aluminum, and the Electroless Nickel then displaces that thin zinc layer with the electroless nickel ions. These ions can be applied at varying levels of Phosphorous depending on the customer’s need or the specification call-out. Easy, right?

“The Electroless Nickel process enhances the life of components exposed to severe conditions of service, particularly in the oil field, spaceflight and marine sectors.”

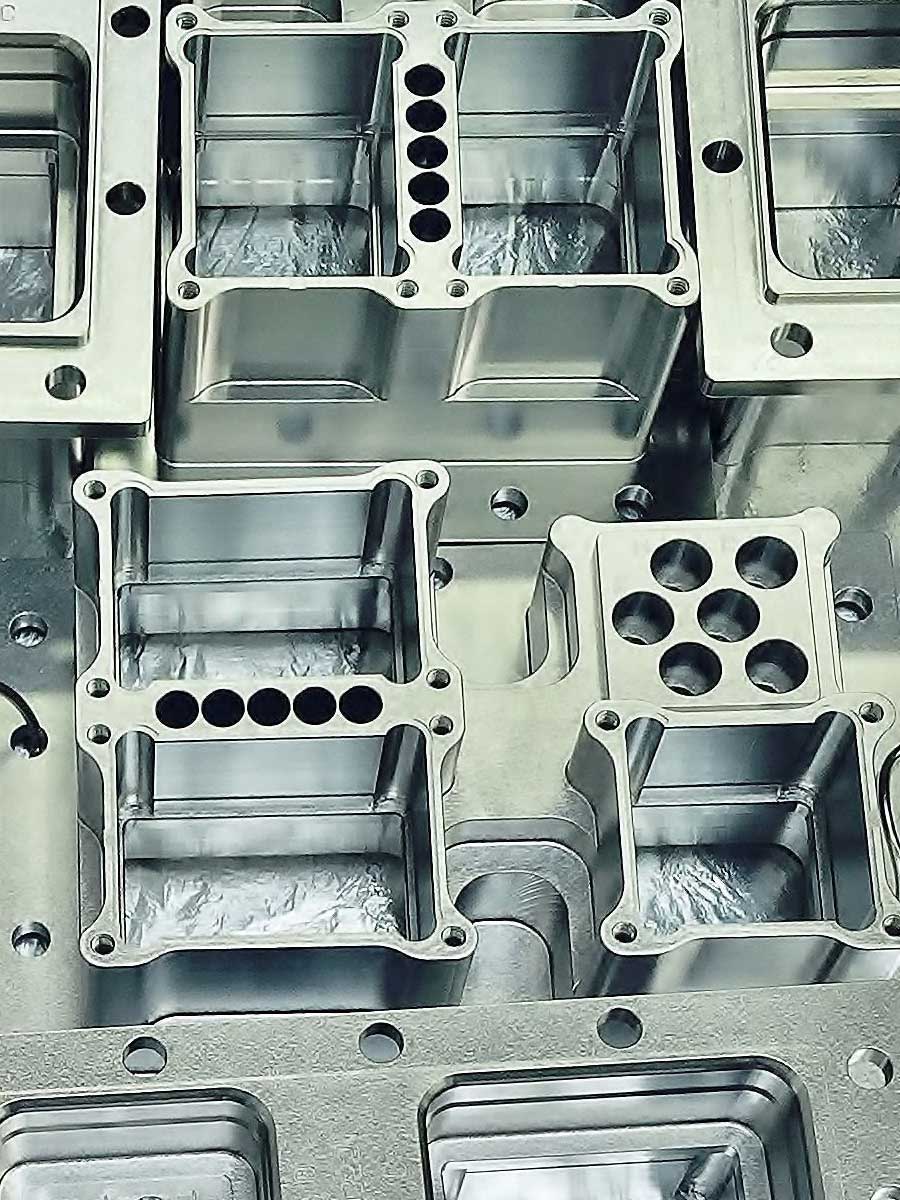

Electroless Nickel has been the coating of choice for many applications due to its exceptional corrosion resistance and high hardness. The process fits a wide window of applications on items such as valves, pump parts, flight parts, and aerospace connectors. The process enhances the life of components exposed to severe conditions of service, particularly in the oil field, spaceflight, and marine sectors. With the correct pretreatment sequence and accurate process control, good adhesion and excellent service performance can be obtained from EN deposits of varying phosphorus levels on a multitude of metallic and non-metallic substrates.

SPI’s Electroless nickel is a conforming coating which allows the deposit thickness to be controlled for tight tolerance finishing on even the most complex geometries. We have many masking techniques for selective plating, so whether it is blind holes, bearing surfaces, deep bores, or threads, you can count on our electroless nickel to meet your engineering needs.

Reach out to us if you have a requirement to use Electroless Nickel on any of your metallic substrates. We currently serve the electronic, semiconductor, medical, and connector sectors as well as many areas of commercial, military, and aerospace manufacturing.

Thanks for visiting our website, tune in next month to learn more about PTFE plating and how Sheffield Platers can help your company to understand the best coating processes for your custom applications.